Borescope for Gas Cylinder Inspection | JEET Industrial Videoscopes

- Share

- Issue Time

- Sep 6,2025

Summary

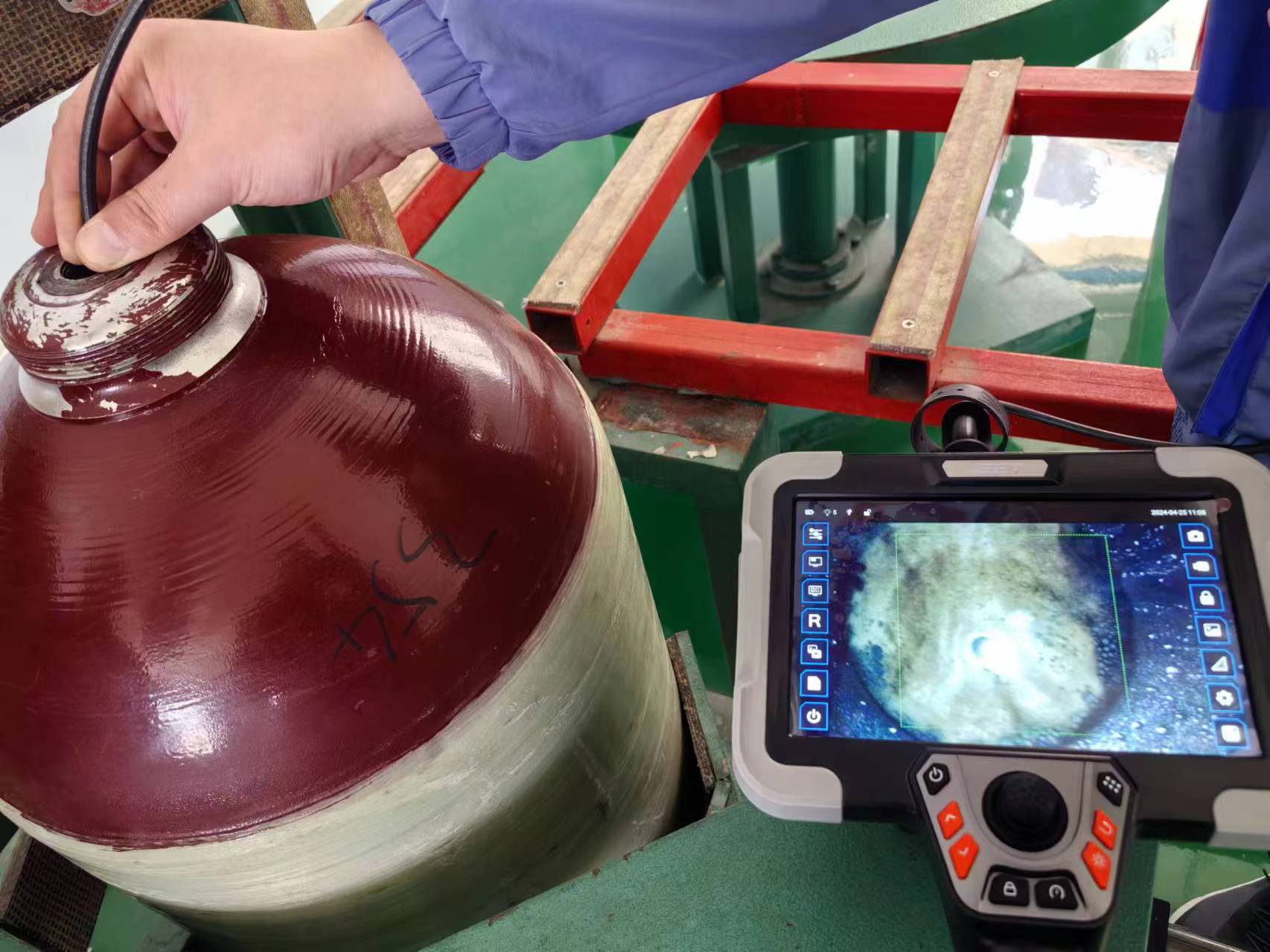

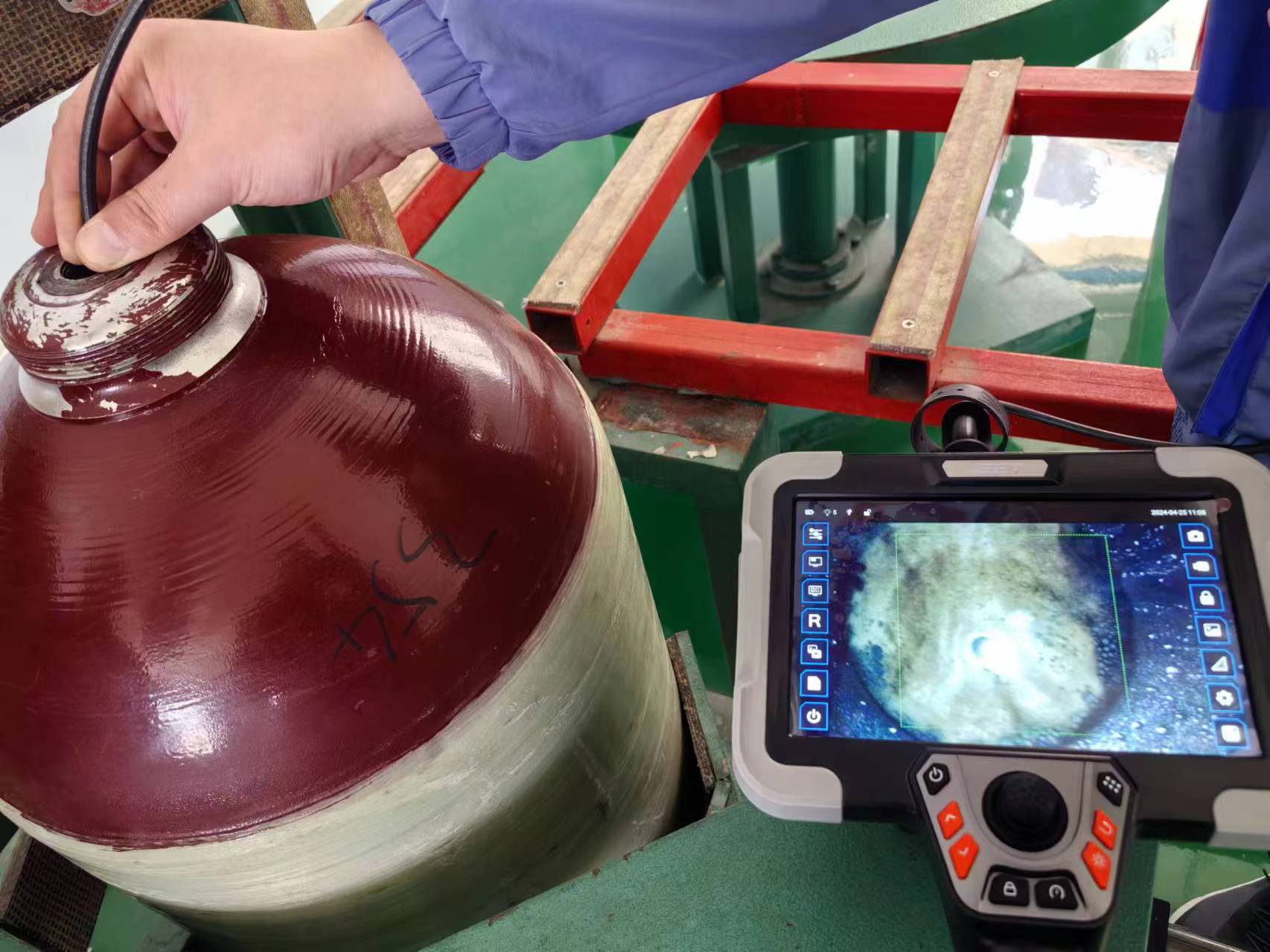

Discover how borescopes are used to inspect the interior of gas cylinders, including medical oxygen, SCUBA, and industrial tanks. Learn best practices for detecting corrosion, cracks, and thread damage. Explore JEET’s advanced industrial borescopes with ultra-thin probes, 360° articulation, and AI-powered defect recognition.

Borescopes for Gas Cylinder Internal Inspection

Why Gas Cylinder Inspections Matter

Gas cylinders are critical for industries ranging from medical oxygen supply and firefighting to industrial gases and SCUBA diving tanks. Over time, the interior surfaces of cylinders can suffer from corrosion, pitting, cracks, or thread damage. If not detected early, these issues may compromise safety, performance, and compliance with international standards.

This is why borescopes are widely adopted to inspect the interior of gas cylinders. With their flexible probes, powerful illumination, and high-resolution imaging, they allow inspectors to identify defects that are invisible to the naked eye.

Applications of Borescopes in Gas Cylinder Inspection

- Thread Inspection – Detect wear, cross-threading, or cracks in cylinder neck threads.

- Corrosion & Pitting – Identify rust or surface damage along cylinder walls.

- Valve Seat Inspection – Ensure the valve connection area remains free of debris or cracks.

- General Surface Integrity – Verify the overall condition of domes, sidewalls, and bottoms.

Types of Borescopes Used for Gas Cylinder Inspections

Based on the references and industry standards, there are several types of borescopes suitable for this task:

- Rigid Borescopes – Provide crystal-clear images, ideal for straight-entry inspections in cylinders with wide openings.

- Flexible Videoscopes – Equipped with articulation, allowing the inspector to navigate bends and thoroughly inspect cylinder threads and domes.

- Dual-View Borescopes – Offer both forward and side views for comprehensive coverage.

- Automated Borescope Systems – Integrated with robotics and AI, capable of 360° spiral scanning and defect detection.

Best Practices for Cylinder Inspections with Borescopes

- Use 8.0–8.5 mm diameter probes for compatibility with cylinder neck openings.

- Choose 180° or 360° articulating tips to cover dome areas.

- Record photos and videos for inspection traceability.

- Integrate results into digital quality certificates (DQC) for compliance and reporting.

Why Choose JEET Borescopes for Gas Cylinder Inspection

At Shenzhen JEET Technology Co., Ltd., we specialize in the development and manufacturing of industrial borescopes. With more than 50 patents and a strong R&D team, our borescopes are trusted in critical industries including aerospace, automotive, police security, and energy.

For gas cylinder inspections, JEET offers:

- Ultra-thin flexible videoscopes (down to 1.0 mm) for narrow access points.

- 360° articulating probes for complete cylinder coverage.

- AI-powered defect recognition for faster and more accurate inspection.

- Rugged, portable designs suitable for both field and laboratory use.

Conclusion

Using a borescope for inspecting the interior of gas cylinders is no longer optional—it is a necessity for ensuring safety, compliance, and performance. Whether you are checking industrial gas bottles, SCUBA tanks, or medical oxygen cylinders, the right borescope solution can significantly improve inspection efficiency.

JEET borescopes combine advanced imaging, durability, and AI-driven analysis, making them an excellent choice for gas cylinder inspection tasks worldwide.