AI intelligent cavity defect identification robot leads industrial quality control into the era of automation

- Share

- Issue Time

- Dec 2,2023

Summary

Automated inner wall surface defect detection robots are an important tool for high-quality, high-efficiency production in modern industrial manufacturing, and with the continuous advancement of science and technology, it will continue to grow and develop, bringing more opportunities to all walks of life. and challenges.

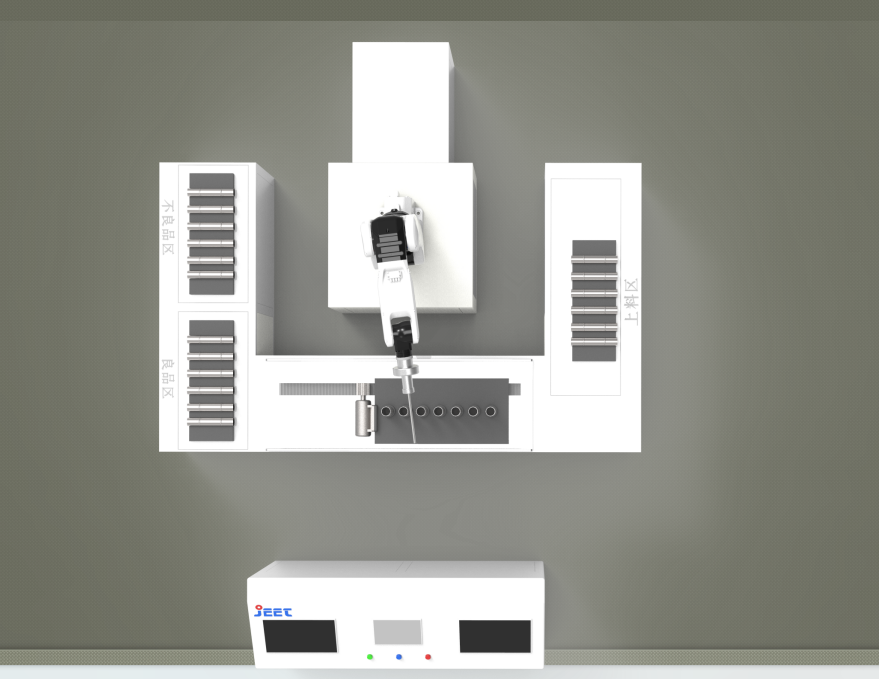

JEET automated inner wall surface defect detection robot

Industrial visual automated inspection is a computer vision technology based on neural network algorithms. It mainly uses the "big model + big data" learning paradigm to analyze and process image or video data to extract key information and perform defect identification, detection, and positioning. , analysis, alarm, recording, traceability and other tasks are of great significance to ensuring product quality and process improvement.

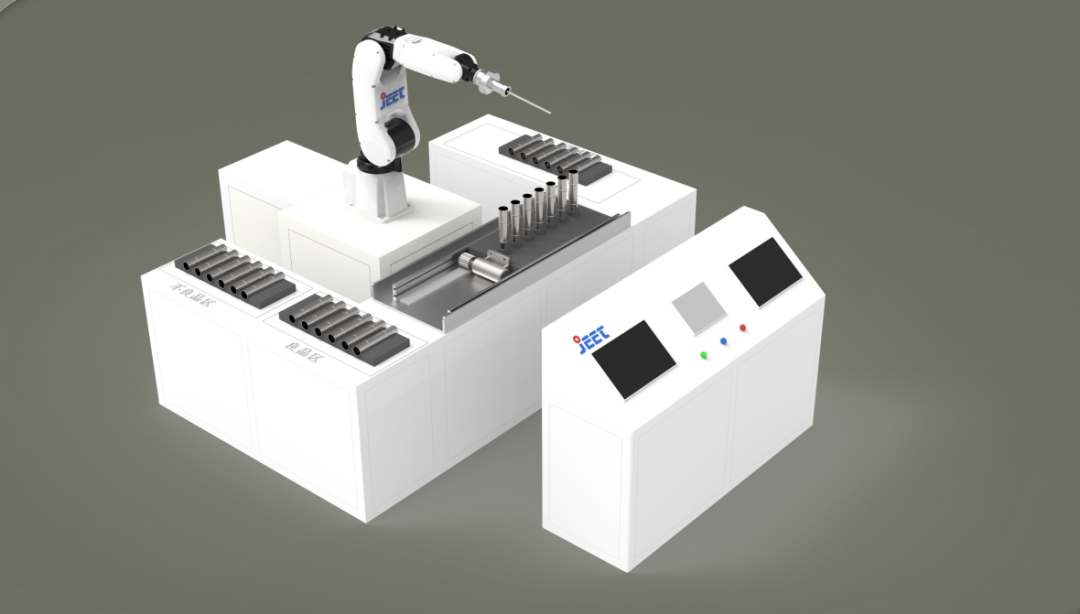

JEET automated inner wall surface defect detection robot is a robot that can automatically, quickly and accurately detect the internal surface quality of objects. It consists of an imaging module, a 6-axis robotic arm and a workbench. It can realize 360° non-blind zone inspection of the inner wall surface of objects to detect whether there are defects, wear, corrosion and other problems on the surface.

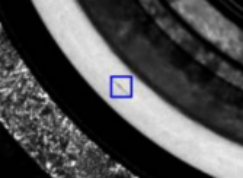

The imaging module is the core component of the automated inner wall surface defect inspection robot. It includes high-precision cameras and lighting equipment. The camera captures an image of the interior surface of an object, and lighting provides the right light so the camera can capture the image clearly. The imaging module analyzes and processes images through computer vision algorithms to detect defects, wear, corrosion and other problems on the surface.

The 6-axis robotic arm is used to perform loading and unloading operations of workpieces and sorting of good and defective products. The robotic arm has high precision and speed and can complete these tasks accurately. In addition, the robotic arm can also achieve a more efficient production process through customized matching automatic loading and unloading modules.

The automated inner wall surface defect detection robot is equipped with a stable workbench to place the workpiece to be inspected. The workbench has high precision and stability, which can ensure the accuracy of the position and attitude of the workpiece during the inspection process, thus improving the accuracy and reliability of inspection.

At the same time, the JEET automated inner wall surface defect detection robot can also customize supporting automatic loading and unloading modules as needed to achieve seamless connection with the production line or other equipment, further improving the automation of the production process.

Detection scenario:

Blisters, scratches, cracks, slag inclusions and other processing defects on the surface or inner wall of the workpiece.

Detection Systems:

1. Defect identification efficiency: 25FPS;

2. Defect identification rate: above 99.99%;

3. Defect resolution: 0.01mm;

4. It can output defect geometric size information, with simple operation and strong versatility. The test results are credible and the data can be traced;

5. Supports incremental AI model training and AI cloud model data fusion. Customers can independently upload data to the cloud, train large AI defect detection models in the cloud, and deploy them locally to the device to update the model and achieve more intelligent and efficient detection;

Automatically identify trachoma

Automatically recognize scratches

In the field of industrial manufacturing

Industrial visual automated inspection can help companies achieve quality inspection and defect identification on automated production lines, and can replace manual dangerous or high-intensity work, thereby improving production efficiency and product quality, and avoiding errors and accidents caused by human factors.

Automated inner wall surface defect detection robots are an important tool for high-quality, high-efficiency production in modern industrial manufacturing, and with the continuous advancement of science and technology, it will continue to grow and develop, bringing more opportunities to all walks of life. and challenges.